Briefly introduce the importance of screw air compressors in industrial operations. Emphasize that true efficiency and longevity come from understanding not just how a compressor works, but what makes it work – its core components.

Understanding the Critical Components of Your Screw Air Compressor for Optimal Performance

- Home

- Blog

- Understanding the Critical Components of Your Screw Air Compressor for Optimal Performance

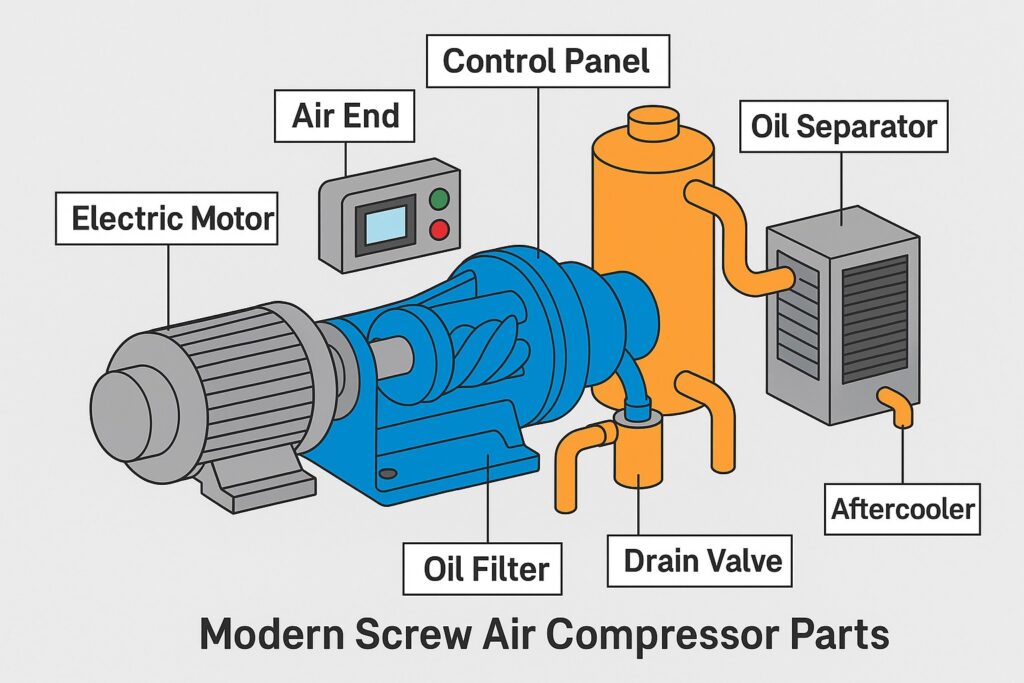

Briefly introduce the importance of screw air compressors in industrial operations. Emphasize that true efficiency and longevity come from understanding not just how a compressor works, but what makes it work – its core components. This article will break down the vital parts of your rotary screw compressor, explaining their function and why proper knowledge is crucial for peak performance and reduced downtime.

1. The Air End: The Heart of Compression

- Explain the role of the male and female rotors in compressing air.

- Discuss the importance of precision machining and lubrication.

- Keywords: air end rebuild, compressor rotors, air end bearing replacement, screw element.

2. The Motor: Powering Productivity

- Types: TEFC, ODP, and the efficiency benefits of VFD (Variable Frequency Drive) motors.

- Importance of correct sizing and electrical connections.

- Keywords: compressor motor efficiency, VFD compressor, electric air compressor motor, motor maintenance.

3. The Oil System: Lubrication, Cooling, and Sealing

- Compressor Oil: Its multifaceted role (lubrication, cooling, sealing, cleaning).

- Oil Filter: Crucial for preventing contaminants from damaging the air end.

- Oil Separator: How it ensures clean air by removing oil mist. Discuss importance of oil separator element replacement.

- Keywords: compressor oil types, synthetic compressor oil, oil filter replacement, oil separator replacement, air-oil separator.

4. Air Intake Filtration: First Line of Defense

- Explain how the air filter protects internal components from dust and debris.

- Impact of a dirty filter on efficiency and lifespan.

- Keywords: air compressor filter, intake filter, air filter element, preventative maintenance.

5. The Cooling System: Managing Heat for Longevity

- Coolers (Air & Oil): Function in dissipating heat generated during compression.

- Fans: Their role in moving air across the coolers.

- Keywords: air compressor cooler, aftercooler, oil cooler, cooling fan, overheating compressor.

6. Control Systems: The Brains of the Operation

- PLC (Programmable Logic Controller): How it monitors and manages compressor functions.

- Sensors: Monitoring pressure, temperature, and other critical parameters.

- Keywords: compressor control panel, PLC programming, pressure sensor, temperature sensor, compressor diagnostics.

7. Pressure Regulation & Valves: Efficiency and Safety

- Inlet Valve: Controls air intake based on demand.

- Minimum Pressure Valve: Ensures sufficient pressure for oil flow and filtration.

- Safety Valve: Essential for preventing over-pressurization.

- Keywords: inlet valve, minimum pressure valve, pressure relief valve, compressor regulation.

Conclusion:

- Reiterate that knowing these parts empowers users to make informed maintenance decisions.

- Encourage regular inspection and OEM parts usage.

- Call to action: Visit our parts store, request a service quote.